Products

-

Precious Metals Horizontal Vacuum Continous Casting Machine

Horizontal vacuum continuous caster: advantages and features

Horizontal vacuum continuous casters are an important part of the metal casting industry and offer a range of benefits and features that make them a popular choice among manufacturers. These machines are designed to produce high-quality metal products with precision and efficiency. In this article, we will explore the advantages and features of horizontal vacuum continuous casters and their impact on the metal casting process.

Advantages of horizontal vacuum continuous casting machine

1. Improve product quality: One of the main advantages of horizontal vacuum continuous casting machines is the ability to produce high-quality metal products. The vacuum environment helps minimize impurities and gas entrapment in the molten metal, resulting in a more uniform and refined product. This improves the mechanical properties and surface finish of the cast metal, making it suitable for a wide range of applications.

2. Enhanced process control: The horizontal vacuum continuous casting machine can precisely control the casting process. The use of vacuum technology allows for better regulation of the cooling rate and solidification of the metal, resulting in a more consistent and controlled casting process. This level of process control helps minimize defects and ensures the production of high-quality castings.

3. Increased Productivity: These machines are designed for continuous operation to achieve high productivity. The horizontal orientation of the casting process allows the production of long continuous castings, reducing the need for frequent mold changes and increasing overall productivity. This makes horizontal vacuum casters a cost-effective solution for manufacturers looking to optimize their production processes.

4. Energy efficiency: The horizontal continuous casting machine uses vacuum technology to reduce energy consumption during the casting process. By creating a controlled solidification environment, the need for excessive heat input is minimized, saving energy and reducing operating costs for manufacturers.

Characteristics of horizontal vacuum continuous casting machine

1. Horizontal Casting Design: The horizontal orientation of these machines allows for continuous casting of long and uniform metal products. This design feature is particularly beneficial for the production of rods, tubes and other long length products, making it a versatile solution for a variety of metal casting applications.

2. Vacuum Chamber: The vacuum chamber in a horizontal continuous caster plays a vital role in creating a controlled environment for the casting process. Vacuum chambers help improve the quality and integrity of cast products by removing air and other impurities from molten metal.

3. Cooling system: These machines are equipped with advanced cooling systems that can precisely control the solidification process. The cooling rate is adjustable to meet the specific requirements of different metal alloys, ensuring the production of high-quality castings with consistent mechanical properties.

4. Automation and control system: The horizontal vacuum continuous casting machine is equipped with advanced automation and control system, which can accurately monitor and adjust the casting process. This level of automation helps minimize human error and ensures repeatability of casting parameters, resulting in consistent product quality.

In summary, horizontal vacuum continuous casters offer a range of advantages and features that make them the first choice for metal casting applications. From improving product quality and process control to improving productivity and energy efficiency, these machines play a vital role in producing high-quality metal products. With advanced design and technology, horizontal vacuum continuous casters continue to drive innovation and efficiency in the metal casting industry.

-

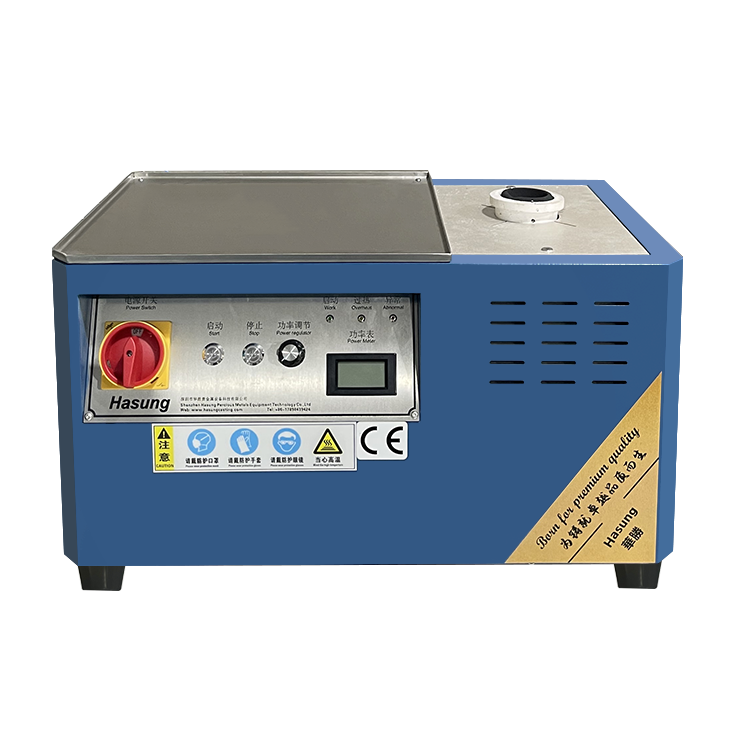

Small Metal Induction Melting Furnace 3kg 4kg

Capabilition of 3kg or 4kg gold capacity, small size, fast melting.

Available for gold, karat gold, silver, copper, alloys, etc.

Compact size, unique design

-

.png)

4 Bars 1kg Automatic Gold Bar Making Machine Hasung

Why do You Choose Hasung Vacuum Gold Bar Casting Machine ?

Hasung Vacuum Bullion Casting Machines compares to other companies

1. It’s a Big different. other companies vacuum are controlled by time. They are not real vacuum. They just pump it symbolically. When they stop pumping, it is not a vacuum, easily leak out. Ours pumps to the setting vacuum level and can maintain the vacuum for a long time.

2. In other words, what they have are the vacuum setting time.

For example, adding inert gas after one minute or 30 seconds is automatic. If it does not reach the vacuum, it will be converted to inert gas. It is In fact, the inert gas and the air are fed at the same time. It is not a vacuum at all. The vacuum cannot be maintained for 5 minutes. Hasung can maintain a vacuum for more than twenty hours.

3. We care about quality with each aspect. Using many world famous brands components.

4. The most advanced and full automatic gold bar casting machine.

-

Small Automatic Gold Bullion Vacuum Casting Machine 1KG Hasung

Why do You Choose Hasung vacuum Gold Bar Casting Machine ?

Hasung Vacuum Ingot Casting machines (HS-GV1) is designed for casting 1kg quality silver and gold bullions. This casting machine comes with the flexibility on moulds to customize your silver and gold bars, ingots and bullions with any of your designs and sizes.

The inert gas chamber of this gold silver bar casting machine ensures that you have a final casting with premium quality and mirror appearance by completely eliminating all forms of porosity, water waves or shrinkage in your final pieces.

Comparing with the traditional method. Your whole casting process will be done under vacuum and inert gas. Thereby giving your casting products a brilliant quality. With the above features your operators is fully guaranteed to operate our equipment easily.

Hasung’s original components are from well-known domestic and world famous brands like Japan SMC, AirTec, Panasonic, Siemens, Mitsubishi and German Schneider, Omron, etc.

-

Platinum Induction Melting Furnace 1kg 2kg 3kg 4kg Hasung

Equipment Introduction:

This device uses high-quality German IGBT module heating modules, which are safer and more convenient. The direct induction of metal reduces losses. Suitable for the melting of metals such as gold and platinum. Hasung’s independently designed and developed heating system and reliable protection function make the entire machine more stable and durable.

-

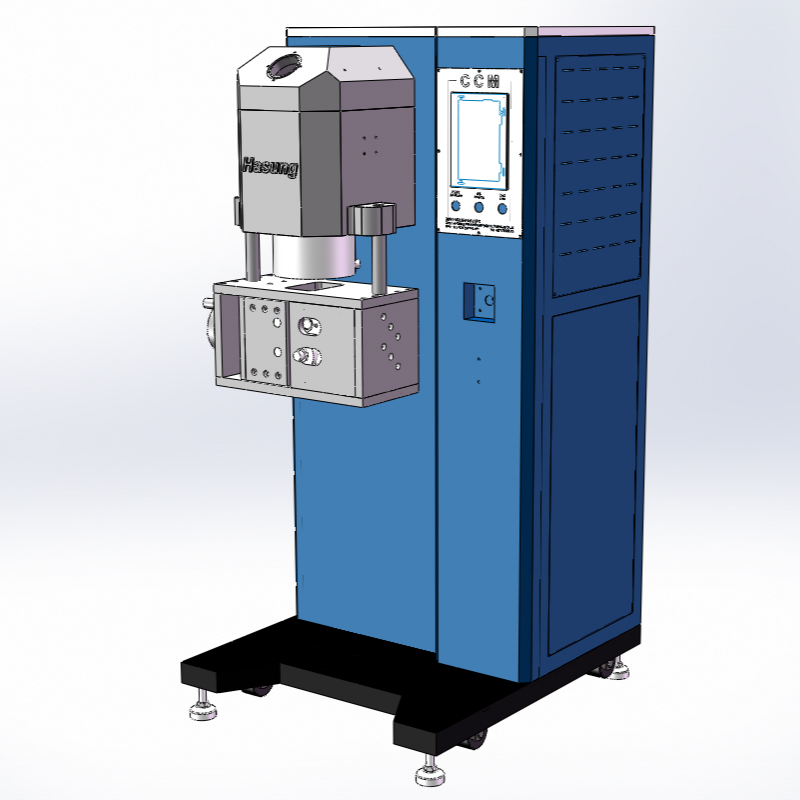

VCT Series Vacuum Pressure Casting Machine with Mitsubishi PLC Touch Screen

NEXT vacuum pressure machine by Hasung is your next machine to create quality.

1 Extra STRONG mixing for good segregation of gold

2. Good melting speed, energy saving

3. Inert Gas – with good filling pieces

4. Precise gauge with improved pressure sensing

5. Easy to maintain

6. Accurate pressure timing

7. Self-diagnosis – Japan Mitsubishi PLC touch panel auto-tuning

8. Easy to operate, one botton to finish the whole casting process9. After mode without oxidation

10. Variable heat for gold loss

11. Vacuum pressure, argon pressure, temperature, pouring time, pressure time, vacuum time.

-

Metal Granulator Machine for Gold Silver Copper 4kg 6kg 8kg10kg15kg

1. With temperature control, accuracy up to ±1°C.

2. Ultra-human design, the operation is simpler than others.

3. Use imported Mitsubishi controller.

4. Silver Granulator with tempterature control (Gold Silver Grains Casting Machine, Silver Granulating Machine).

5. This machine adopts IGBT advanced heating technology, the casting effect is very good, the system is stable and safe, molten gold capacity is optional, and the granulated metal specification is optional.

6. The granulation speed is fast and no noise. Perfect advanced testing and protection functions make the whole machine safe and durable.

7. The machine has a split design and the body has more free space.

-

VCTV Series Jewelry Vacuum Pressure Casting Machine with Vibration System

NEXT vacuum pressure machine by Hasung is your next machine to create quality.

1. Two modes for flask with flange and flask without flange

2. Vibration system for fine casting

3. Extra mixing for good segregation of gold

4. Good melting speed, energy saving

5. Inert Gas – with good filling pieces

6. Precise gauge with improved pressure sensing

7. Easy to maintain

8. Accurate pressure timing

9. Self-diagnosis – Japan Mitsubishi PLC touch panel auto-tuning

10. Easy to operate, one botton to finish the whole casting process11. After mode without oxidation

12. Variable heat for gold loss

13. Vacuum pressure, argon pressure, temperature, pouring time, pressure time, vacuum time, vibration time, vibration hold time can be set, Program for flask with flange, program for flask without flange, both are available, auto mode and manual mode are available.

-

Tilting Induction Melting Furnace For Gold Platinum Palladium Rhodium 1kg 5kg 8kg 10kg

The design of this tilting melting system is based on the actual needs of the project and process, using modern high-tech technology. Safety guarranted.

1. Adopt German high-frequency / Low Frequency heating technology, automatic frequency tracking and multiple protection technology, which can melt metals in a short time, save energy and work efficiently.

2. Using electromagnetic stirring function, no segregation in color.

3. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

4. Using PID temperature control system, the temperature is more accurate (±1°C) (optional).

5. The HS-TFQ smelting equipment is independently developed and manufactured with advanced technical level products for the smelting and casting of gold, silver, copper, etc.

The HS-HS-TFQ series is designed for melting platinum, palladium, Rhodium, gold, silver, copper and other alloys.

6. This equipment apply many foreign famous brands components.

7. It keeps heating while pouring metal liquids at a great condition which enables users to get great quality casting.

-

-1.png)

Automatic Gold Bar Vacuum Casting Machine 60KG

Why do You Choose Hasung Vacuum Gold Bar Casting Machine ?

Hasung Vacuum Bullion Casting Machines are designed and manufactured specially for precious metals industry.

The emergence of this equipment completely replaces the traditional production process of gold and silver bars, completely solving the problems of shrinkage, water waves, oxidation, and unevenness of gold and silver. It uses full vacuum melting for rapid prototyping, which can replace the current domestic gold bar production process and make the domestic gold bar casting technology reach the international leading level. The products produced by this machine have a smooth and polished surface, no holes, and almost negligible losses. The use of fully automated control can achieve the operation of multiple machines by ordinary workers, greatly saving production costs. It is an essential tool for major precious metal refineries.

Hasung’s the original components are well-known brands from Taiwan, Japan, France and Germany.

-

Platinum Granulating System Granulating Machine 10kg

Hasung Platinum Shot Maker Granulating Machine compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.Hasung summarizes the defects of past products, and continuously improves them. The specifications of Hasung Platinum Shot Maker Granulating Machine can be customized according to your needs.

The main advantages of the new generations of shotmaker

Easy installation of the granulating tank with platform

High quality granulating performance

Ergonomically and perfectly balanced design for safe and easy handling

Optimized streaming behavior of the cooling water

Reliable separation of water and granules -

Continuous Casting Machine for Gold Silver Copper Alloy 20kg 30kg 50kg 100kg

1.As soon as silver gold strip wire tube rod continuous casting machine for jewelry was launched on the market, it received positive feedback from many customers, who said that this type of product can effectively solve their needs.Moreover,the product is widely used in Metal Casting.

2.Continuous Casting Machine for Making Rod Strip Pipe with 20kg 30kg 50kg 100kg compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.Hasung summarizes the defects of past products, and continuously improves them. The specifications of Continuous Casting Machine for Making Rod Strip Pipe with 20kg 30kg 50kg 100kg can be customized according to your needs.