Powder Atomization Plants

Making Metal Powder

The Powder Metallurgy (PM) process is making metal powders.

The metal powder water atomizer is used to produce high quality and homogenous master grains and alloy grains, and also the powder, starting from raw material molten by induction heating in a protective atmosphere, and then When casting the powder, will adopt the high pressured water gun to break the molten metal into fine particles. Mostly, used in metal refining industry.

The Gas Atomizer is characterized by small environmental pollution, high degree of ball-shape powder, low oxygen content and fast cooling rate and so on. Through many years’ constant innovation and improvement, our company has updated our gas atomization powder-manufacturing technique and technology several times in order to produce metal and alloy powders of high performance. Currently, the technology has become the leading factor to support and promote atomization powder-manufacturing equipment, new material research and new technology development.

The operating principle of atomizing equipment refers to the powder-manufacturing process that smelting metal or alloy under certained condition with metal liquid poured obliquely to heat preservation crucible flowing out through liquid diversion mouth (downward), and takes advantage of the high pressure gases of nozzle to crush metal liquid into large amounts of fine and small liquid drop; The flying liquid drops solidify into ball-shape or sub ball-shape particles and thus complete the whole powder-manufacturing process. Mostly, used in metal 3D printing industry.

-

Metal Flakes Processing Machine Gold Flakes Making Equipment for Gold Refining

Equipment introduction:

1. Adopt medium frequency induction, short melting time and high work efficiency.

2. The melting chamber applies inert gas which is used to prevent the oxidation of metal materials and the incorporation of impurities. For this purpose, it is suitable for high-purity metal materials or smelting containing easily oxidized elements.

3. The mechanical stirring function under vacuum state is adopted, and the color formation is not segregated.

4. The smelting is protected by high-purity inert gas, so the graphite ruthenium has very little oxidation loss.

5. Using Taiwan Weinview/Siemens PLC controller, the operation is simple.

6. The mold is automatically heated during the pouring process to ensure the quality of the casting.

7. With many world famous brands components to ensure premium quality.8. Mostly used for gold refining.

-

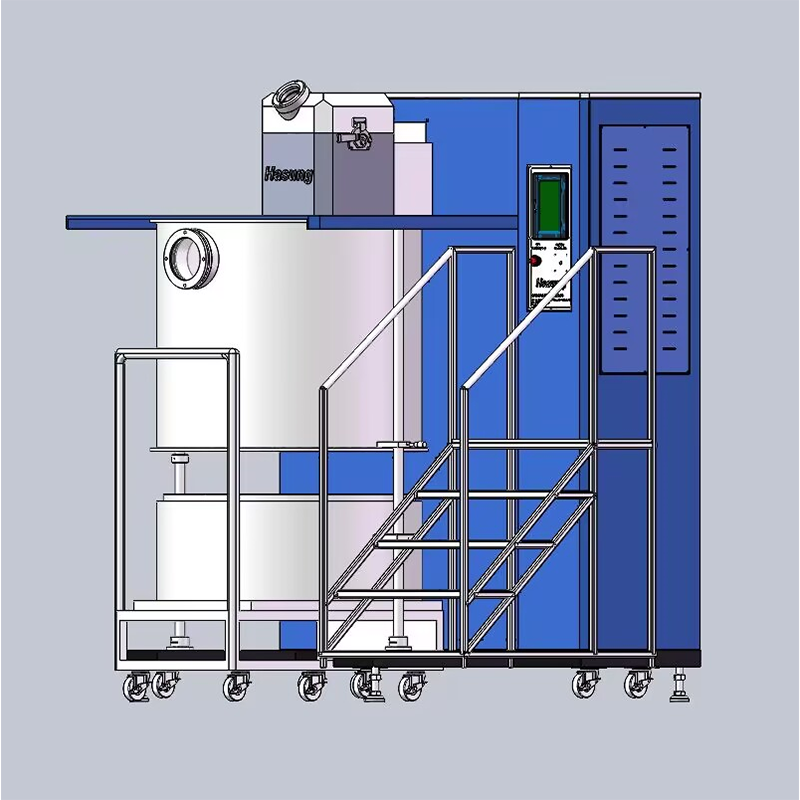

Metal Powder Water Atomizer For Precious Metal Powder Gold Silver Copper

Product Specifications

Induction heating under the protection of inert gas, using graphite crucible, melting temperature up to 1600 degrees. HT high temperature type can be used, using ceramic crucible (graphite susceptor), the melting temperature can reach 2000 degrees. A hot gas supply system can be added, where the gas is heated to 500 degrees for the manufacture of finer metal powders. The equipment produces spherical metal powders with good fluidity and particle sizes between 10 and 200 microns, even more up to #400, 500#. It can be used in manufacturing processes such as laser selective sintering and powder metallurgy.Advantages of Hasung AU series equipment:

– Compact structure and easy operation

– Flexible and efficient production of small batches of metal powders

– Easy and fast alloy change and nozzle replacement

– High flour extraction rate and milling loss rate as low as 1/1000

– Stable production processImportant Features of Hasung AU Series Devices:

– Graphite crucible can be heated up to 2000 degrees in protective gas environment

– Microprocessor controlled induction motor (400 volts, 3 phase power)

– Excellent liquid metal mixing function, which can fuse and smelt different metals before gas atomization

– In the environment of protective gas, the feeding system can be added to change the alloy composition

– Precise temperature control using N-type and S-type thermocouples

– Crucible capacity 1500cm3, 3000cm3 and 12000cm3 optional

– Use argon or nitrogen up to 30 atmospheres

– A gas heating system can be added to heat the gas to 500 degrees for the production of powders with small particles

– Quick and easy switching between two milling modes for efficient production of powders of different particle sizes

– Optimized airflow pattern to avoid satellite particles for good powder flow

– Collection of dry metal powder in a dusting tower under protective gas

– Collection of fines by means of a pneumatic filter

– Can store more than 100 parameter settings

– The device can be serviced remotely via the GSM unit -

100 mesh – 400 mesh Metal Powder Water Atomizer Machine

It is mainly suitable for making powder (or granular) materials in an atomizing tank after melting metals or metal alloys (ordinary melting or vacuum melting can be used). Mainly used in universities, scientific research institutes, etc. Metal atomization powder can be produced by high pressure water atomization according to the powder application.

This equipment is also suitable for the production and research of additive manufacturing (gold refining) metal powder preparation in universities and scientific research institutes.

The equipment is also suitable for the research and production of various kinds of stainless steel, alloy steel, copper powder, aluminum powder, silver powder, ceramic powder and brazing powder.