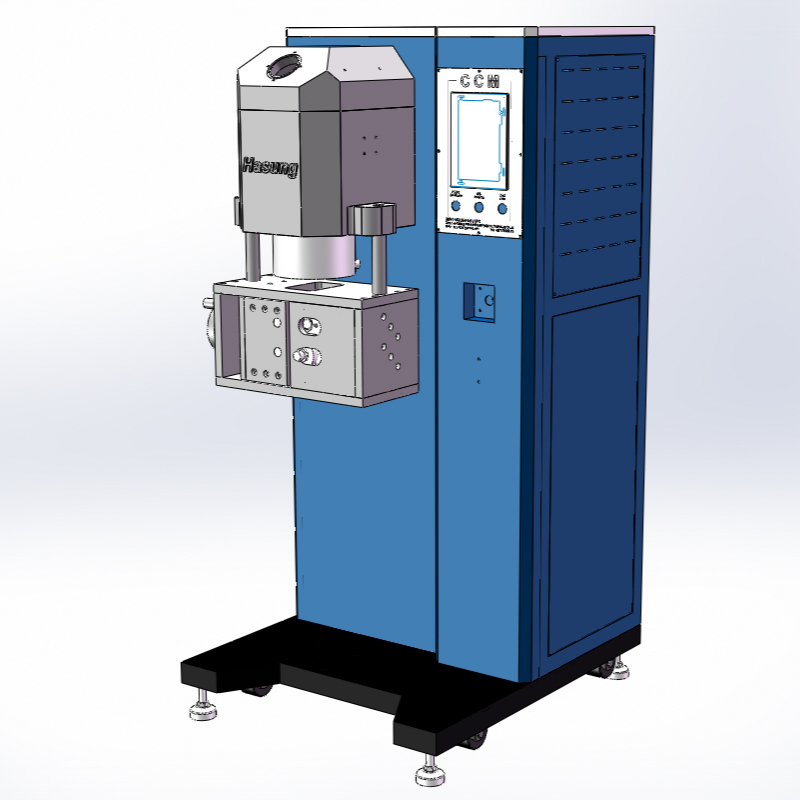

VC Series Jewelry Vacuum Pressure Casting Machine

Features

1. Operation method: One-key operation to complete the entire process, POKA YOKE foolproof system.

2. Control system: Mitsubishi PLC+Human-machine interface intelligent control system (optional).

3. Using German high-frequency heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving, and high work efficiency.

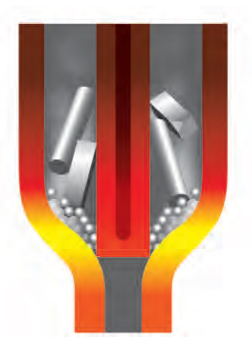

4. The closed type/channel type + vacuum/inert gas protection melting chamber can prevent the oxidation of molten raw materials and the mixing of impurities. This equipment is suitable for the casting of high-purity metal materials or elemental metals that are easily oxidized.

5. Adopt closed/channel type + vacuum/inert gas to protect the melting chamber, melting and cooling are performed at the same time, the time is halved and the production efficiency is increased.

6. Melting in an inert gas environment, the oxidation loss of the carbon mold is almost negligible.

7. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color.

8. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

9. Using PID temperature control system, the temperature is more accurate (±1°C).

10. HS-VC gold and silver casting forming equipment/full-automatic production line is independently developed and manufactured with advanced technical level products for the smelting and casting of gold, silver, copper and other alloys.

11. This equipment uses Mitsubishi PLC program control system, SMC pneumatic and Panasonic servo motor drive and other domestic and foreign brand components.

12. Melting, electromagnetic stirring, and refrigeration in a closed/channel + vacuum/inert gas protection melting room, so that the product has the characteristics of no oxidation, low loss, no porosity, no segregation in color, and beautiful appearance.

Why Do You Choose Hasung Vacuum Pressure Casting Machine?

Hasung Vacuum Casting Machines compare to other companies

1. Energy saving. With low power consumption of 5KW 220V single phase.

2. Good melting speed. Melting speed is within 2 minutes which is as fast as others' machines of 8W 380V.

3. 1kg or 2kg capacity could be equipped with 220V single phase which is suitable for the clients who don't have 380V 3 phases electricity. Main power 5KW, casting quantity in 18 kt up to 2,000 g. 380V 8KW is optional which melting speed is faster.

4. Hasung original parts are from well-known domestic Japan and German brands.

Technical Parameters

| Model No. | HS-VC1 | HS-VC2 |

| Voltage | 220V, 50/60Hz single phase; 380V 3 phases | 220V single phase / 380V, 50/60Hz, 3 phases |

| Power Supply | 5KW / 8KW | 5KW/8KW |

| Max Temp | 1500°C | |

| Melting Time | 3-5 min. / 2-3 min. | 10-20 min. / 3-6 min. |

| Protective Gas | Argon / Nitrogen | |

| Temp Accuracy | ±1°C | |

| Capacity (Gold) | 1kg | 2kg |

| Casting pressure | 0.1-0.3Mpa (Adjustable) | |

| Max flask size | 4"x10" | |

| Vacuum Pump | High quality vacuum pump | |

| Application | Gold, K gold, silver, copper and other alloys | |

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | |

| Cooling type | Water chiller(sold separately) or Running water | |

| Dimensions | 680*680*1230mm | |

| Weight | approx. 120kg | approx. 120kg |

Product Display

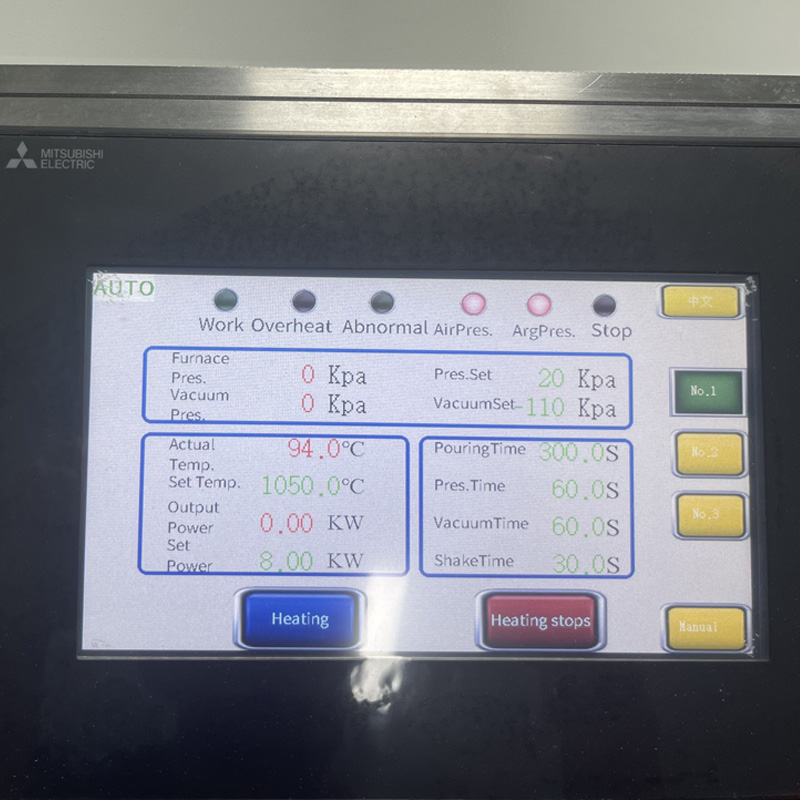

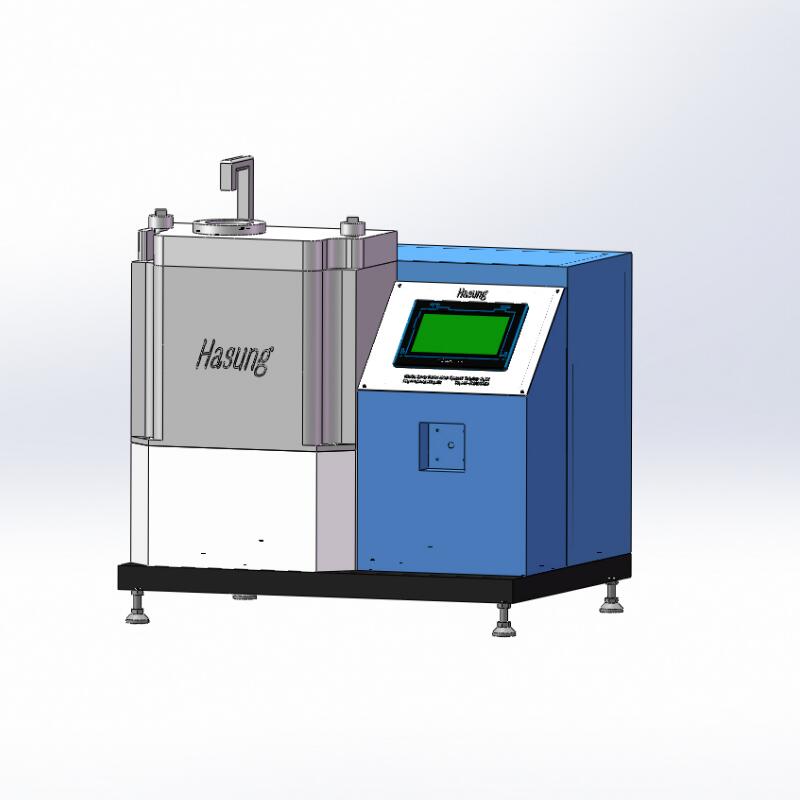

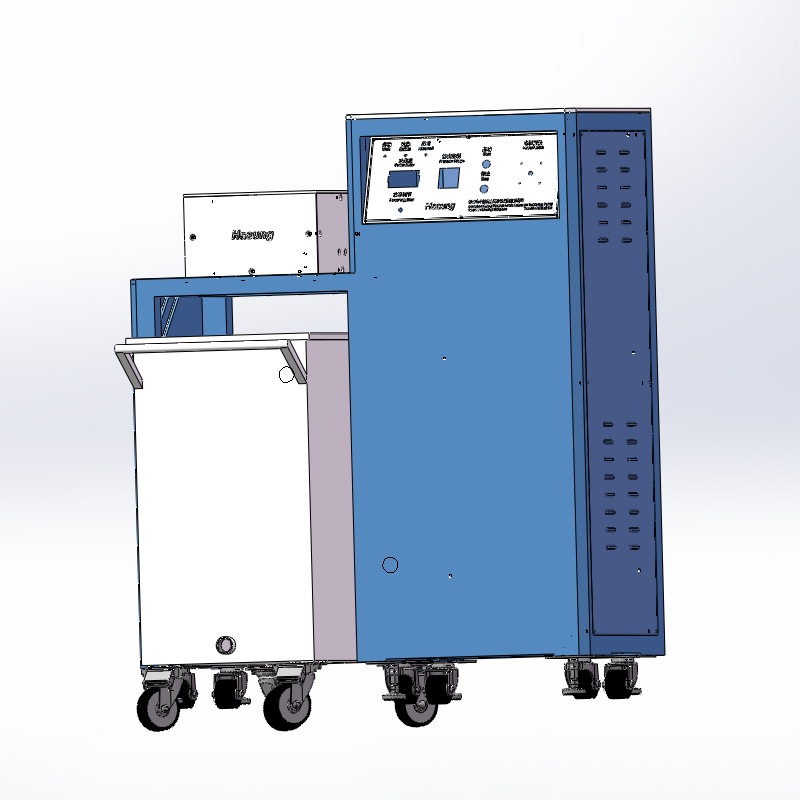

VCT Series vacuum pressure casting machine is equipped with Mitsubishi PLC touch panel controller, you can use manual operation step by step or automatic operation for casting. With PLC touch panel, parameters such as temperature, vacuum, vacuum time, pouring time, pressure, etc can be easily seen.

The VCT induction vacuum pressure casting machine is optional to be equipped with vibration system which allows you to have better casting results, especially for your thin pieces products, Karat gold jewellery. It's the same functions as TVC model, the only difference is the style and smaller machine size.

With Mitsubishi PLC touch panel controller, simple but great working performance.

*You can do manual casting or fully automatic casting.

*You can set parameters by yourself accorind to your products features.

*You can set storage casting momeries by yourself.

The casting machine applies Germany IGBT induction heating technology, Germany Schneider electrics, Germany Omron, Japan Mitsubishi electrics, Japan Panasonic serve drive, Japan SMC, etc.

Use high quality components, fine craftmanship.

Technical Parameters

| Model No. | HS-VCT1 | HS-VCT2 |

| Voltage | 220V, 50/60Hz single phase; 380V 3 Phases | 220V single phase / 380V, 50/60Hz, 3 phases |

| Power Supply | 5KW / 8KW | 5KW/8KW |

| Max Temp | 1500°C | |

| Melting Time | 6-12 min. / 2-3 min. | 10-20min. / 3-6 min. |

| Protective Gas | Argon / Nitrogen | |

| Temp Accuracy | ±1°C | |

| Capacity (Gold) | 1kg | 2kg |

| Casting pressure | 0.1-0.3Mpa (Adjustable) | |

| Max. Flask Size | 4"x10" | |

| Vacuum Pump | High quality vacuum pump | |

| Application | Gold, K gold, silver, copper and other alloys | |

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | |

| Controller | Mitsubishi PLC Touch Panel | |

| Cooling type | Water chiller(sold separately) or Running water | |

| Dimensions | 680*680*1230mm | |

| Weight | approx. 120kg | approx. 120kg |

Product Display

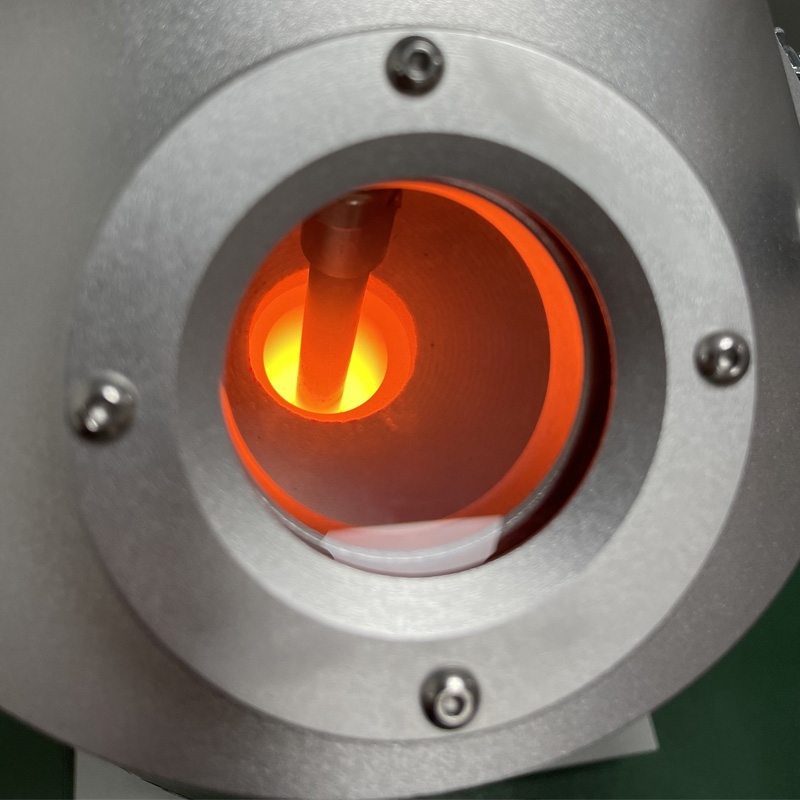

Vacuum pressure casting machine consumables:

1. Graphite crucible

2. Ceramic gasket

3. Ceramic jacket

4. Graphite stopper

5. Thermocouple

6. Heating coil

.png)