VCT Series 3kg Automatic Vacuum Pressure Casting Machine with PLC Touch Screen

Features

1. Gas Wash Procedure

. Crucible loading operation creates oxygen

. The Gas Wash procedure removes the oxygen in a fast and efficient way then refills back the chambers with argon or nitrogen.

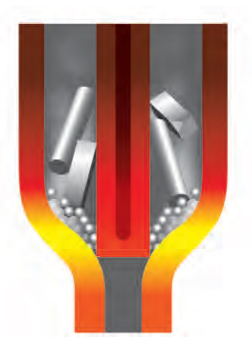

2. Melting

. Advanced and accurate temperature control for the melted alloys.

. Medium frequency induction heating stirs the melted alloy and leads to a perfect homogeneity.

. Melting in an inert gas environment, the oxidation loss of the carbon mold is almost negligible.

3. Injection and Compression

. VCT has the unique feature to have the injection rate controllable and programmable for the timer.

. The metal enters smoothly inside the plaster mould. Then, a strong compresion takes place on the tree after filling and during solification phase.

4. This equipment uses Germany Siemens PLC program control system, Festo pneumatic valve and AirTec compoents, Taiwan Weinview touch screen, Germany Schneider, Japan Shinko, Japan SHAKO, Japan SMC, Germany SLGPC, and other foreign brand components.

Why Do You Choose Hasung Vacuum Pressure Casting Machine?

Hasung Automatic Vacuum Pressure Casting Machines compare to other companies

1. Energy saving. With strong overpressure for high precision products casting.

2. Good melting speed. Melting speed is within 2 minutes which is as fast as others' machines of 15W 380V for 3kg capacity.

3. Max. flask size 5"x16" allows a big capacity and long size casting.

4. Hasung original parts are from well-known domestic Japan and Germany brands such as Germany Siemens, Taiwan Weinview, Germany Schneider, Japan Shinko, Japan SHAKO, Japan SMC, Japan AirTec, Germany SLGPC, FESTO, etc.

Technical Parameters

| Model No. | HS-VCT3 |

| Voltage | 380V, 50/60Hz 3 Ph |

| Power | 15KW |

| Max. temp. | 1500°C |

| Temp Accuracy | ±1°C |

| Melting speed | 2-3 min. |

| Casting pressure | 0.1Mpa - 0.3Mpa |

| Capacity | 3kg Au, 1.5kg Ag |

| Max. cylinder size | 5"*16" (5“*12” standard) |

| Application metals | Gold, K gold, Silver, Copper, alloy |

| Memory | Yes. Programmed |

| Vacuum pressure setting | Available |

| Overpressure setting | Available |

| Second time overpressure setting | Available |

| Temperature setting | Available |

| Pouring time setting | Available |

| Pressure time setting | Available |

| Pressure hold time setting | Available |

| Vacuum time setting | Available |

| Overheat protection | Yes |

| Vibration system | Yes |

| Magnetic stirring | Yes |

| Thermocouple type | K type 1200 °C |

| Operation method | One-key operation to complete the entire casting process |

| Control system | Siemens PLC + Taiwan Weinview touch panel |

| Operation mode | Automatic mode / Manual mode (both) |

| Inert gas | Nitrogen/argon (optional) |

| Cooling type | Water chiller (Sold separately) |

| Vacuum pump | Optional (built external) |

| Dimensions | 750*850*1300mm |

| Weight | approx. 280kg |

Product Display

Product Display

VCT Series vacuum pressure casting machine is equipped with Siemens PLC touch panel controller, you can use manual operation step by step or automatic operation for casting. With PLC touch panel, parameters such as temperature, vacuum, vacuum time, pouring time, pressure, etc can be easily seen.

The VCT induction vacuum pressure casting machine is optional to be equipped with vibration system which allows you to have better casting results, especially for your thin pieces products, Karat gold jewellery.

With Siemens PLC touch panel controller, simple but great working performance.

*You can do manual casting or fully automatic casting.

*You can set parameters by yourself accorind to your products features.

*You can set storage casting momeries by yourself.

The casting machine applies Germany Infineon IGBT induction heating technology, Germany Schneider electrics, Germany Omron, Japan Mitsubishi electrics, Japan Panasonic serve drive, Japan SMC, etc.

Use high quality components, fine craftmanship.

Vacuum pressure casting machine consumables:

1. Graphite crucible

2. Ceramic gasket

3. Ceramic jacket

4. Graphite stopper

5. Thermocouple

6. Heating coil

7. Filter

8. Gaskets

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur