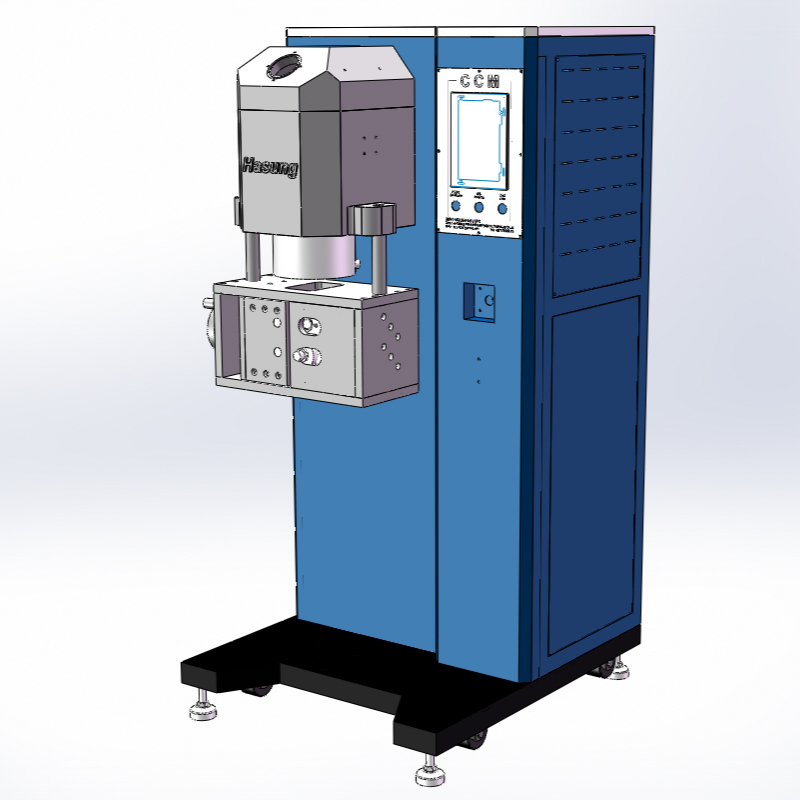

Product Detail

Machine Video

Product Tags

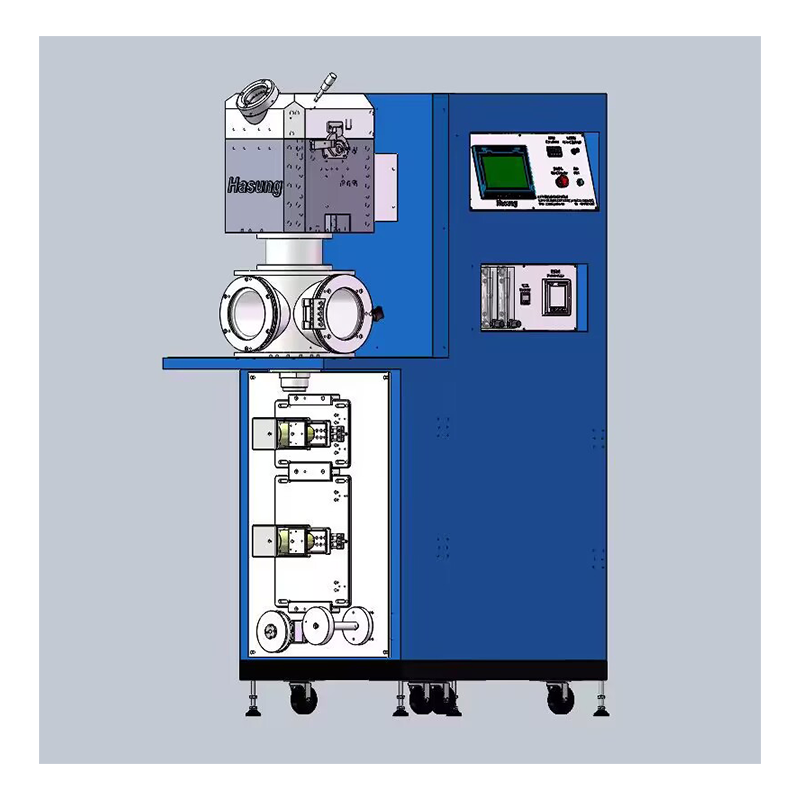

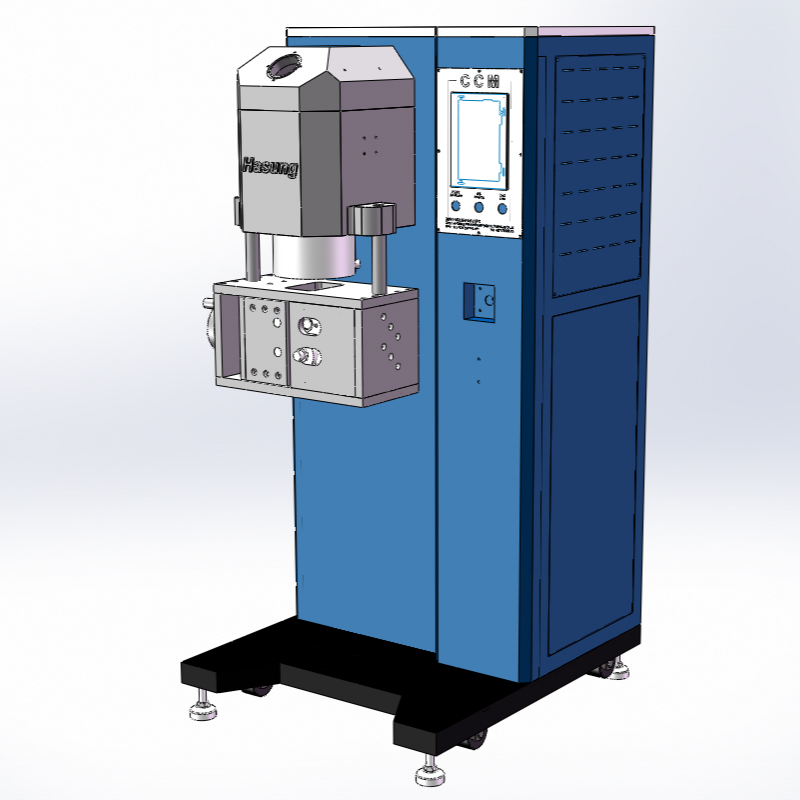

| Power Supply |

380V 50/60Hz,3 phase |

| Power Input |

8KW |

15KW |

| Max Temp |

1500°C |

| Melting speed |

3minutes |

3- 5min |

| Capacity |

2kg(18K gold) |

5kg(18K gold) 10kg, 20kg, 30kg, 50kg, 100kg optional |

| Suitable for |

K-Gold,Gold, silver, copper |

| Maximum flasks diameter |

can be customized |

| Operation method |

One-key operation to complete the entire process, POKA YOKE foolproof system |

| control system |

Taiwan Weinview / Siemens PLC+Human-machine interface intelligent control system (optional) |

| Blanketing with inert gas |

Nitrogen/argon selection |

| Temperature accuracy |

±1℃ |

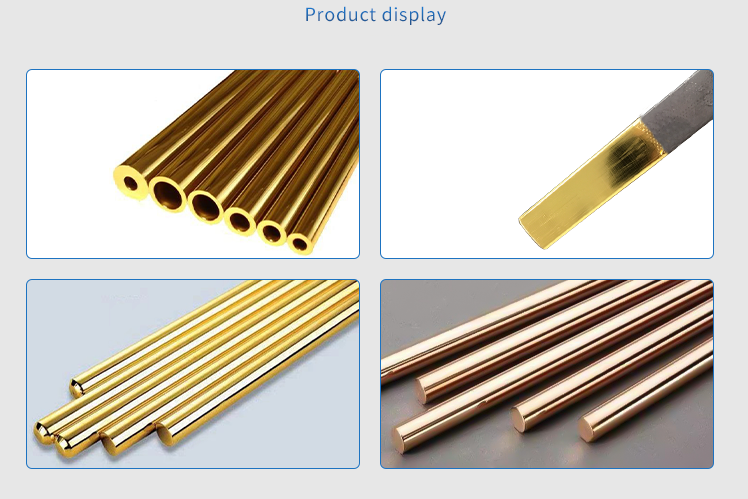

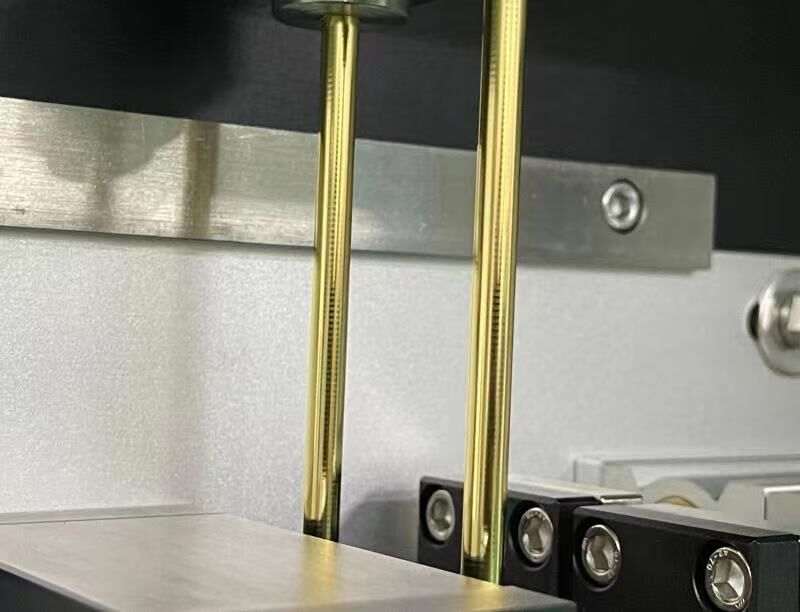

| Product shape |

strip, square, tube, can be customized strip |

| Water pressure |

0.2-0.4Mpa |

| Water temp |

18-25C |

| Cooling type: water |

Water chiller or Running water |

| Vacuum pump |

High vacuum level vacuum pump (vacuum level is according to customer's request) |

| Dimensions |

960*600*1580mm |

| Weight |

280KG |

280KG |

Previous:

Continuous Casting Machine for Gold Silver Copper Alloy

Next:

High Vacuum Continuous Casting Machine For New Materials Casting Bonding Gold Silver Copper Wire