Product Detail

Machine Video

Product Tags

| Model No. |

HS-VCC4 |

HS-VCC5 |

HS-VCC6 |

HS-VCC8 |

HS-VCC10 |

| Voltage |

|

|

|

|

|

| Power |

|

|

|

|

|

| Capacity (Au) |

4kg |

5kg |

6kg |

8kg |

10kg |

| Max Temp |

1500°C |

| Casting Speed |

200mm-1200mm/min. |

| Casting Diameter |

4mm-20mm |

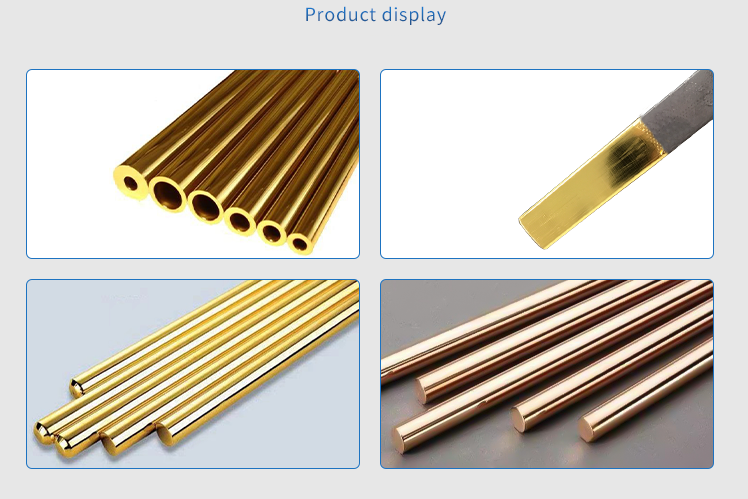

| Casting product |

Rods, sheets, square, etc. |

|

| Temp Accuracy |

±1°C |

|

| Temp detector type |

PID, K type thermocouple |

| Vacuum Pump |

High level degree vacuum pump, vacuum degree (optional) |

| Application metals |

Gold, silver, copper and alloys |

| Operation method |

Manual key operation |

| Control System |

Human-machine interface intelligent control system |

| Cooling type |

Water chiller (Sold separately) |

| Dimensions |

800*870*1760mm |

| Weight |

approx. 300kg |

Previous:

Continuous Casting Machine for Gold Silver Copper Alloy

Next:

High Vacuum Continuous Casting Machine For New Materials Casting Bonding Gold Silver Copper Wire