Hasung-8HP horizontal rolling mill

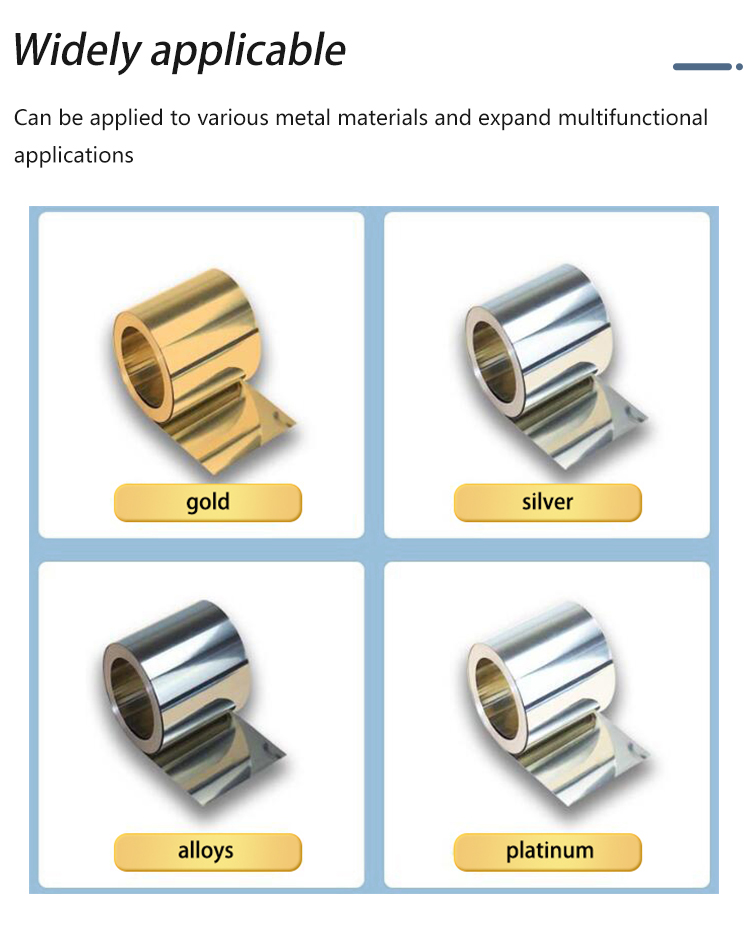

The 8-horsepower horizontal rolling mill is a precision experimental equipment specially developed for the field of metal materials. It is widely used in the research of metal material properties, metal powder rolling and forming, gold/precious metal extraction experiments, and other scenarios, especially suitable for laboratory and small-scale process development needs.

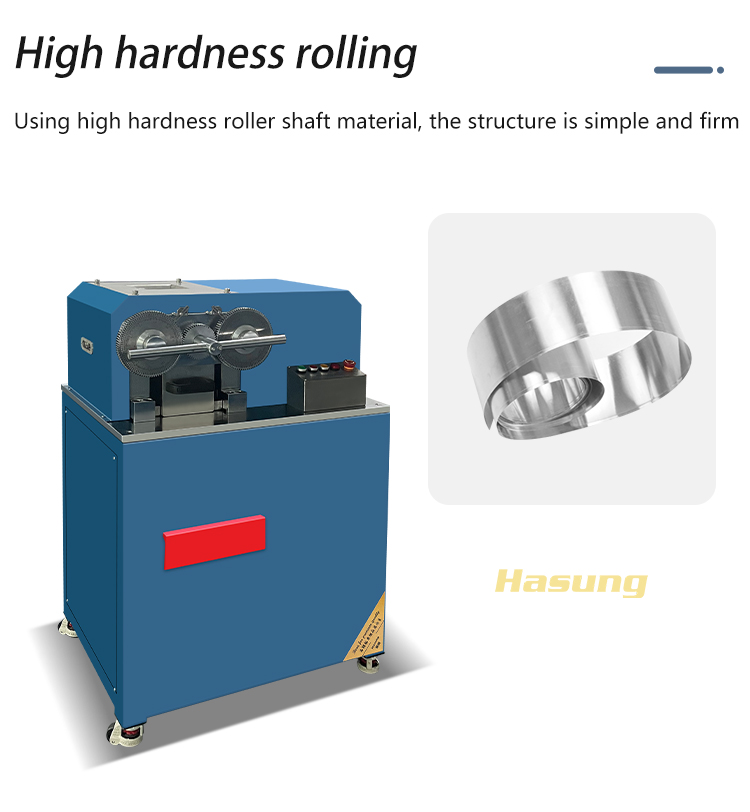

The core of the equipment adopts the principle of double roll extrusion, and the roller body is made of high hardness and wear-resistant materials (such as D2 mold steel). Combined with an automatic oil supply system, it can achieve continuous lubrication and cooling of the roller surface, ensuring the stability of the rolling process and effectively extending the service life of the equipment. During operation, the gap between the rollers can be adjusted with precision knobs (with an accuracy of up to 0.1mm), flexibly adapting to the pressing and forming requirements of metal foil and powder blanks with different thicknesses (0.1mm-20mm).

For complex process scenarios, the equipment supports customized upgrades for multiple rollers: by increasing the number of rollers and optimizing the arrangement of the roller system, multiple continuous rolling processes can be achieved, completing the forming process from rough billet to precision finished product in one go, greatly improving experimental efficiency and product consistency.

The equipment adopts a horizontal structure as a whole, with a compact volume (about 850 × 620 × 1250mm), simple and intuitive operation, and is equipped with overload protection device to ensure the safety of the experimental process.

| Product Parameters | |

| Model | HS-HRM8 |

| Voltage | 380V, 50/60Hz, 3-phase |

| Power | 5.6KW |

| Roller shaft size | 120 * 200mm (diameter * width) |

| Maximum opening | 20mm |

| Thinnest size | 0.1mm |

| Application materials | platinum, palladium, rhodium, gold, K gold, silver, copper, alloys, etc |

| Equipment size | 850 × 620 × 1250mm |

| Net weight of equipment | about600KG |

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur