2022 Good Quality Gold Silver Granulating Equipment - Vacuum Granulating System for Gold Silver Copper 20kg 50kg 100kg – Hasung

2022 Good Quality Gold Silver Granulating Equipment - Vacuum Granulating System for Gold Silver Copper 20kg 50kg 100kg – Hasung Detail:

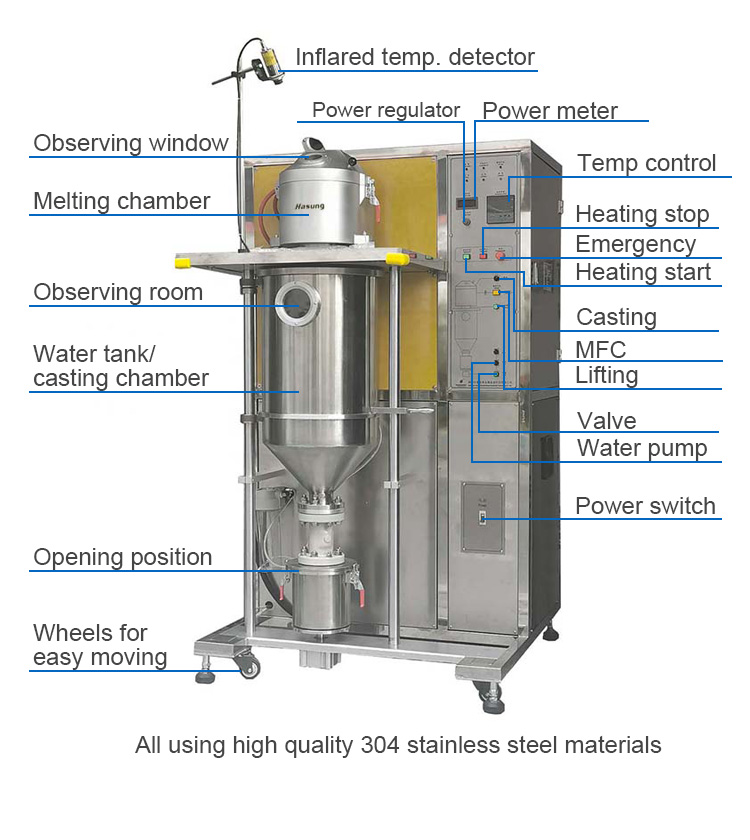

The vacuum granulator uses inert gas to protect the smelting metal. After the smelting is completed, the molten metal is poured into the water tank under the pressure of the upper and lower chambers. In this way, the metal particles we obtain are more uniform and have better roundness.

Secondly, because the vacuum pressurized granulator is protected by inert gas, the metal is casted in the condition of completely isolating the air, so the surface of the casted particles is smooth, free of oxidation, no shrinkage, and extremely high gloss.

Precious metal vacuum granulator, including a crucible for holding metal and a heating device for heating the crucible; a sealing chamber is provided outside the crucible; the sealing chamber is provided with a vacuum tube and an inert gas tube; the sealing chamber is provided with a chamber door for easy metal insertion and a cover plate; the bottom of the crucible is provided with a bottom hole for the outflow of the metal solution; the bottom hole is provided with a graphite stopper; the upper part of the graphite stopper is connected with an electric push rod for driving the graphite stopper to move up and down; a turntable is arranged below the bottom hole; A driving device is connected; a cooling water tank is arranged under the turntable for cooling the metal droplets falling from the turntable; the turntable and the cooling water tank are located in the sealed chamber; the side wall of the cooling water tank is provided with a cooling water inlet and a cooling water outlet; The cooling water inlet is located in the upper part of the cooling water tank, and the cooling water outlet is located in the lower part of the cooling water tank. The formed metal particles are relatively uniform in size. The surface of the metal particles is not easy to be oxidized, and the inside of the metal particles is not easy to generate pores.

Hasung Vacuum Machine Compare To Other Companies

1. It’s a Big different. many companies vacuum are controlled by time.

They are not vacuum.They just pump it symbolically.When they stop pumping, it is not a vacuum.

Ours pumps to the set vacuum level and can maintain the vacuum.

2. In other words, what they have are the vacuum setting time.

For example, adding inert gas after one minute or 30 seconds is automatic.

If it does not reach the vacuum, it will be converted to inert gas. It is In fact, the inert gas and the air are fed at the same time. It is not a vacuum at all. the vacuum cannot be maintained for 5 minutes. Hasung can maintain a vacuum for more than twenty hours.

3.We are not the same. We have drawn a vacuum. If you stop the vacuum pump, it can still maintain the vacuum. For a certain period of time, we will reach the set After setting the value, it can automatically switch to the next step and add inert gas.

4.Hasung the original parts are from well-known domestic Japan and German brands.

Technical Parameters

| Model No. | HS-VGR20 | HS-VGR30 | HS-VGR50 | HS-VGR100 |

| Voltage | 380V 50/60Hz; 3 phases | |||

| Power | 30KW | 60KW | ||

| Capacity (Au) | 20kg | 30kg | 50kg | 100kg |

| Application metals | Gold, Silver, Copper, Alloy | |||

| Casting time | 10-15 min. | 20-30 min. | ||

| Maximum temperature | 1500 ℃ (degrees celsius) | |||

| Temperature accuracy | ±1℃ | |||

| Control type | Mitsubishi PID control system / Mitsubishi PLC Touch panel | |||

| Casting grain size | 1.80 mm – 4.00 mm | |||

| Vacuum Pump | High level quality vacuum pump / Germany vacuum pump 98kpa (Optional) | |||

| Shielding gas | Nitrogen/Argon | |||

| Machine Size | 125*980*1950mm | |||

| Weight | Approx. 700kg | |||

Product Display

Product detail pictures:

Related Product Guide:

We strive for excellence, services the customers", hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for 2022 Good Quality Gold Silver Granulating Equipment - Vacuum Granulating System for Gold Silver Copper 20kg 50kg 100kg – Hasung , The product will supply to all over the world, such as: Jeddah, USA, Armenia, Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, please do not hesitate to contact us.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!