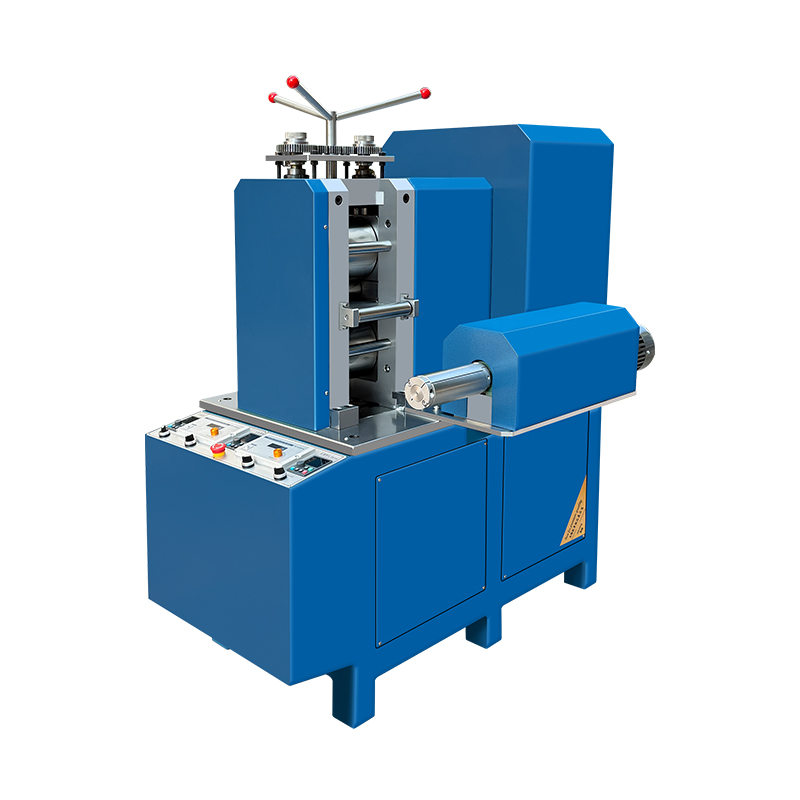

In the field of gold foil processing, technological innovation has always been a key driving force for industry development. The emergence of the Hasung 4 rollers gold foil rolling mill is like a brilliant new star, bringing a new revolution to gold foil processing. It is gradually changing the traditional pattern of gold foil processing with its unique design and excellent performance, becoming a powerful assistant for many gold foil production enterprises.

1.Exploring the working principle of Sikun gold foil rolling mill

The Hasung gold foil rolling mill mainly achieves the pressing of gold foil through the coordinated operation of four pressure rollers. Its working principle is based on the ductility of metals, gradually compressing gold nuggets into extremely thin gold foil under strong pressure.

Inside the rolling mill, four pressure rollers are installed in a specific arrangement. Usually, the upper and lower pressure rollers are the main pressure rollers responsible for applying the main pressure and initially thinning the gold nuggets; The left and right pressure rollers play an auxiliary and regulating role, ensuring the flatness and uniformity of the gold foil during the pressing process. After the gold nugget is fed into the rolling mill, it first passes between the upper and lower pressure rollers and is subjected to a huge vertical pressure, causing the gold nugget to start spreading and thinning. Next, under the action of the left and right pressure rollers, the gold foil is further stretched and adjusted in the horizontal direction, making the thickness of the gold foil more uniform and consistent.

This unique four roll design can provide a more stable and uniform pressure distribution compared to traditional two roll or three roll laminating machines, effectively avoiding problems such as uneven thickness and uneven surface of gold foil during the pressing process, greatly improving the quality and production efficiency of gold foil.

2.The advantages of Sikun gold foil rolling mill are fully demonstrated

(1) Excellent precision control

The Sikun gold foil rolling mill is equipped with an advanced roller distance adjustment system, allowing operators to accurately adjust the distance between the rollers according to different gold foil thickness requirements. This high-precision control capability enables the thickness error of the pressed gold foil to be controlled within a very small range, meeting the strict requirements of the high-end market for consistency in gold foil thickness. For example, in the production of gold foil used for high-end jewelry and art decoration, the thickness accuracy requirement is extremely high. The Sikun gold foil press can easily handle it, ensuring that each piece of gold foil has excellent quality.

(2) Efficient production capacity

The collaborative work of four pressure rollers enables the Sikun gold foil rolling mill to process more gold materials per unit time. Compared to traditional rolling milles, its production efficiency has been significantly improved. Taking common gold foil specifications as an example, the output of the Sikun gold foil rolling mill can reach [X] square meters per hour, which is several times the output of a regular two roll rolling mill. For large-scale gold foil production enterprises, this means that they can complete orders in a shorter time and improve their market competitiveness.

(3) Wide material adaptability

In addition to gold, the Sikun gold foil rolling mill can also process various metal materials such as silver, copper, aluminum, and various alloy materials. This feature has greatly expanded its application scope in the metal processing industry. Whether used for making gold and silver foil decorations, metal packaging materials, or metal foil in the electronics industry, the Sikun Gold Foil rolling mill can leverage its advantages and provide effective solutions for the production needs of different industries.

(4) Stable and reliable performance

The rolling mill adopts high-quality materials and advanced manufacturing processes in the design and manufacturing process, ensuring the stability and reliability of the equipment. Its key components, such as pressure rollers and transmission systems, have been carefully designed and rigorously tested to withstand long-term, high-intensity workloads. At the same time, the equipment is equipped with comprehensive safety protection devices and fault diagnosis systems, which not only ensure the safety of operators, but also timely detect and solve problems that occur during the operation of the equipment, reducing maintenance costs and downtime.

3.The Sikun gold foil rolling mill has a wide range of applications

(1) Golden foil art field

In the creation of gold foil art, the Sikun gold foil rolling mill plays a crucial role. Artists use the high-quality gold foil they press to create exquisite gold foil paintings, sculptures, and other works of art. The delicate texture and unique luster of gold foil add unparalleled charm to artworks. For example, in the restoration and creation of some large-scale religious murals, it is necessary to use a large amount of uniformly thick and high-quality gold foil. The Sikun gold foil press can meet this demand and provide strong support for the inheritance and development of cultural and artistic undertakings.

(2) Jewelry industry

The jewelry industry has extremely high quality requirements for gold foil. The gold foil pressed by the Sikun gold foil press has precise thickness and smooth surface, making it very suitable for use in jewelry inlay, decoration and other processes. Whether it’s making gorgeous gold jewelry or decorating diamonds, gemstones, and other items with exquisite gold foil, the gold foil produced by the Sikun Gold Foil Press can showcase excellent effects, enhancing the overall quality and value of jewelry.

(3) Building Decoration Industry

In the field of architectural decoration, gold foil is often used for the decoration of luxury hotels, palaces, temples and other buildings, creating a magnificent atmosphere. The Sikun gold foil rolling mill can produce high-quality gold foil on a large scale, meeting the dual requirements of quantity and quality of gold foil in building decoration engineering. The pressed gold foil can maintain a bright color and perfect flatness for a long time after being pasted onto the surface of the building, adding unique artistic charm to the building.

(4) In the field of electronics industry

With the continuous development of electronic technology, the application of metal foil in the electronics industry is becoming increasingly widespread. The Sikun gold foil press can press metal materials into ultra-thin foil that meets the requirements of the electronics industry, which is used to manufacture electronic components such as capacitors and electronic circuit boards. Its high-precision pressing ability ensures the uniformity of foil thickness and the stability of electrical performance, providing reliable material support for the development of the electronics industry.

4.Outlook for the future: Development trend of Sikun gold foil rolling mill

With the continuous advancement of technology and the increasing diversification of market demand, the Sikun gold foil rolling mill will also usher in new development opportunities and challenges. In the future, the Sikun gold foil rolling mill will develop towards intelligence and automation. By introducing advanced sensor technology and automated control systems, the equipment will be able to achieve real-time monitoring and precise control of the production process.

The operator only needs to input the required specifications of the gold foil on the control interface, and the rolling mill can automatically complete the entire pressing process, greatly improving production efficiency and product quality stability. Meanwhile, energy conservation and environmental protection will also become an important direction for the development of Sikun gold foil rolling mill. R&D personnel will be committed to optimizing the energy utilization efficiency of equipment, reducing energy consumption, and minimizing environmental impact. By adopting new energy-saving motors and optimizing the transmission system, the Sikun gold foil rolling mill will not only achieve efficient production but also better meet the requirements of sustainable development.

The Sikun gold foil rolling mill, with its unique advantages, is playing an increasingly important role in gold foil processing and related industries. It not only brings higher production efficiency and better product quality to enterprises, but also provides strong support for the innovative development of various industries. I believe that in the future, with the continuous innovation of technology, the Sikun gold foil rolling mill will continue to lead the development trend of the gold foil processing industry, creating more value and surprises for us.

Post time: May-29-2025