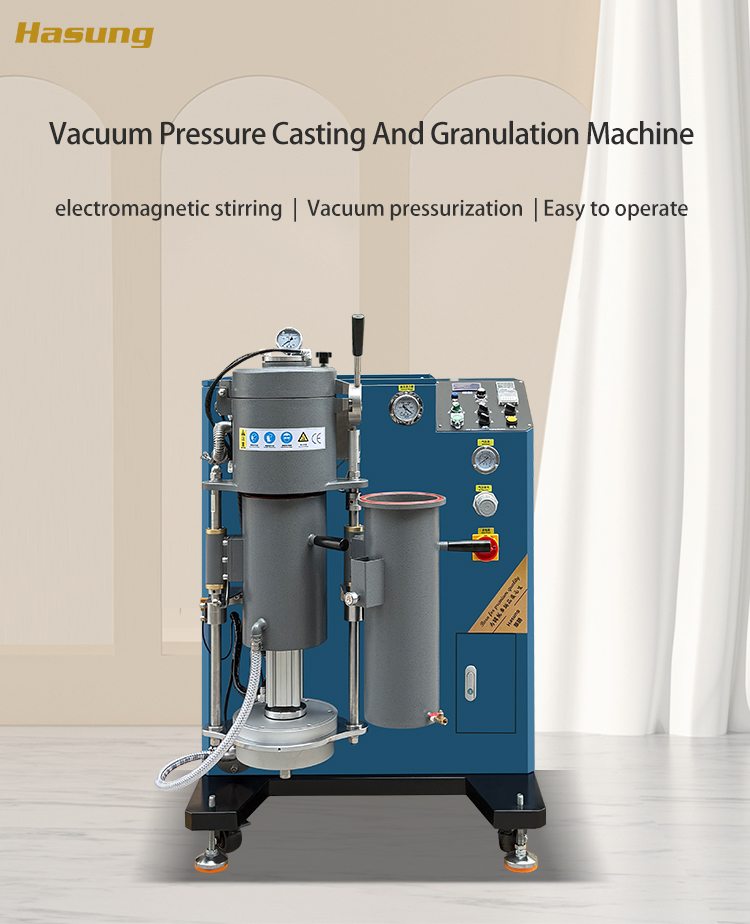

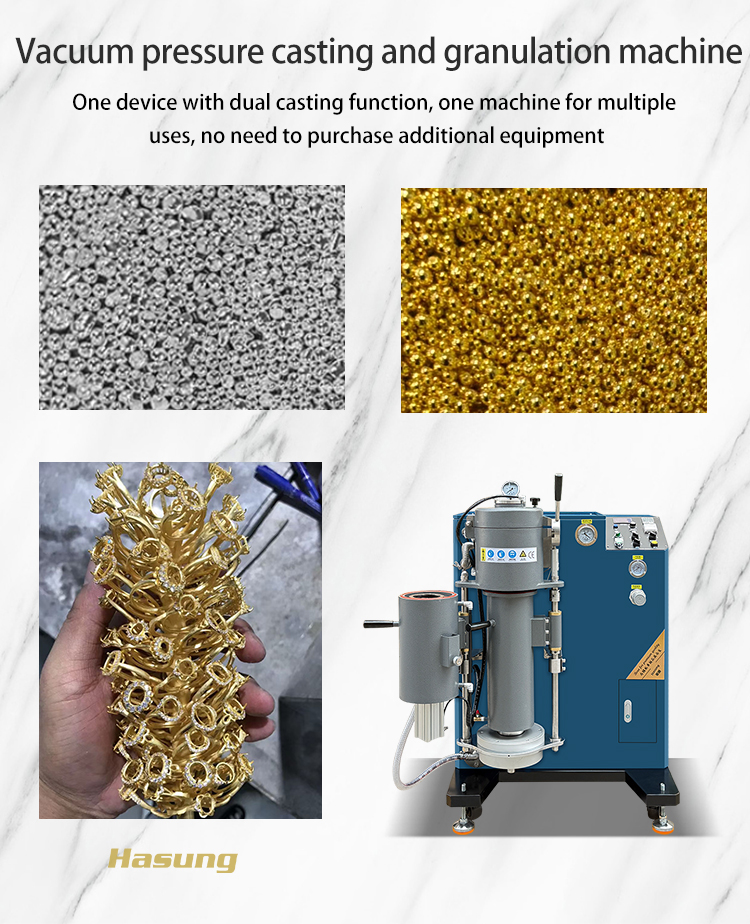

Jewelry Casting Machine and granulation machine-Hasung

Inverted granulation integrated machine: a dual energy casting tool with one machine

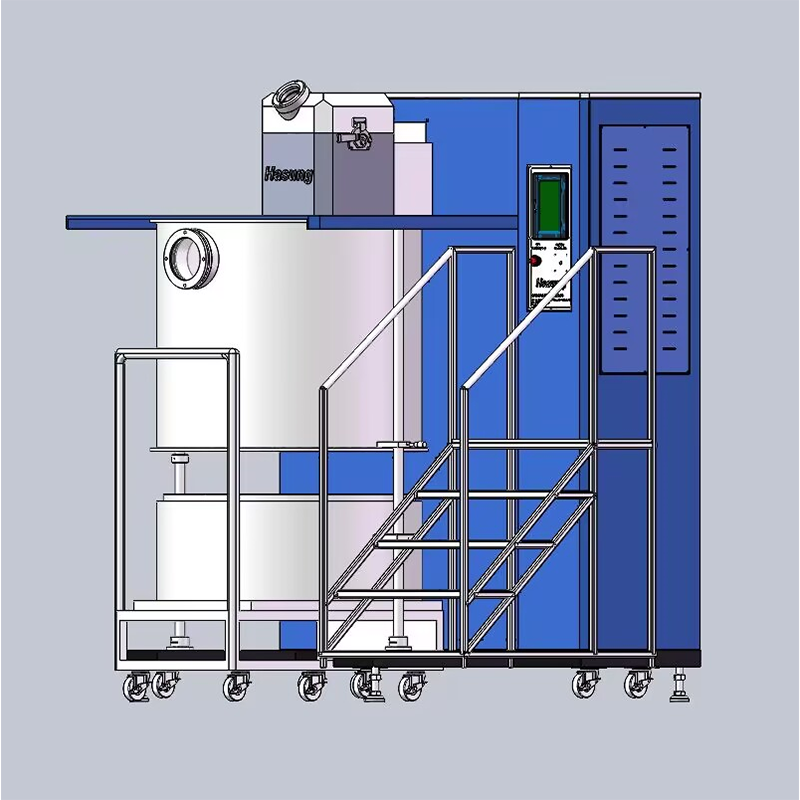

The Hasung inverted mold granulation integrated machine is a casting equipment that integrates dual core functions - it supports both fine inverted mold casting and metal granulation, and can cover various production needs without the need for additional equipment procurement. Its design is equipped with core technologies such as vacuum pressurization and electromagnetic stirring: the vacuum environment can avoid the formation of bubbles in the metal liquid, while electromagnetic stirring allows the molten liquid to mix more evenly. Combined with an intelligent temperature control system, it can stably cast highly complex handicrafts (such as silk pieces and precision jewelry), as well as mass produce uniform metal particles (gold and silver particles, etc.), balancing precision and mass production efficiency.

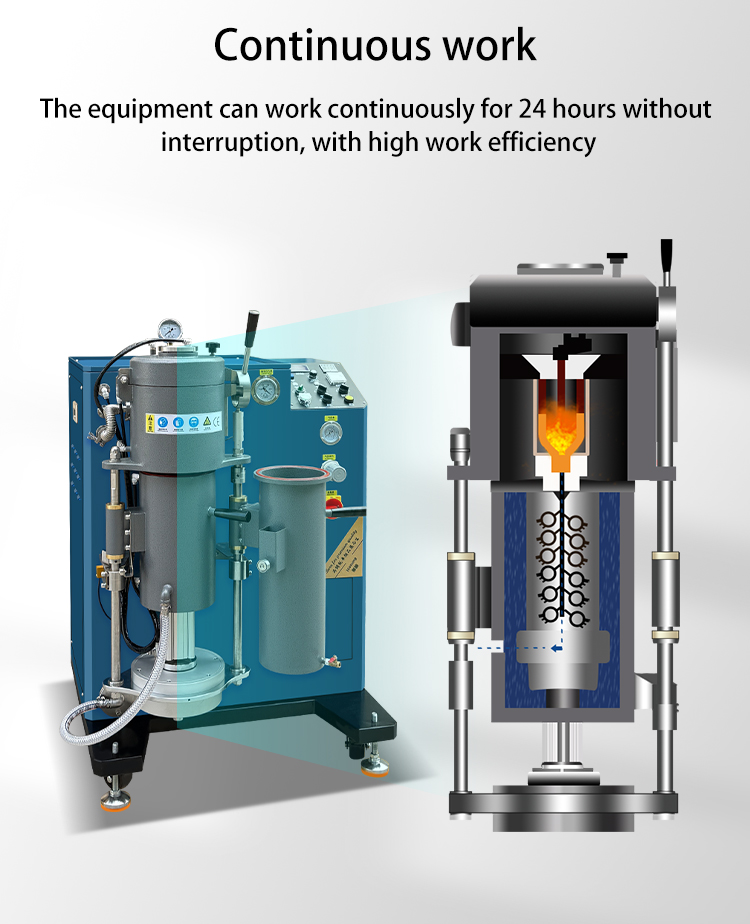

Efficient and intelligent casting solution

This device is designed with the core features of "efficiency and ease of use": using induction heating technology, single piece casting only takes about 3 minutes, and supports 24-hour continuous work, greatly improving production rhythm; Equipped with a simple control interface for operation, even beginners can quickly get started. At the same time, the device comes with multiple security protection mechanisms to reduce operational risks. From the perspective of functional advantages, it solves the pain points of traditional casting equipment such as "single function, low efficiency, and multiple defects in finished products". Whether it is batch jewelry casting in the jewelry industry, complex ornament production in the handicraft industry, or particle preparation in the metal processing field, it can adapt to the production needs of different scenarios.

Flexible production tools adapted to multiple industries

In practical applications, the operation of the integrated reverse molding and granulation machine can be flexibly adjusted according to industry scenarios:

Jewelry industry: By using precious metal raw materials in equipment and vacuum pressure casting mode, fine casting of rings, pendants and other jewelry can be completed within 3 minutes. Electromagnetic stirring ensures uniform color and no segregation of jewelry;

Crafts industry: For complex shapes such as filigree pieces and three-dimensional ornaments, utilizing the precision molding capability of equipment, delicate textures and complex structures can be achieved in one casting;

Metal processing industry: Switching to granulation mode allows for mass production of uniform gold and silver particles, meeting the needs of raw material packaging, jewelry accessories, and more.

| Product Parameters | |

| Model | HS-VPC-GS |

| Voltage | 380V,50/60Hz, 3 phases |

| Power | 10kW |

| Capacity (Au) | 2kg |

| Temperature range | Standard 0~1150 ℃ K type/optional 0~1450 ℃ R type |

| Overpressure time delay setting | Yes |

| Noble gas | Nitrogen/Argon |

| Cooling method | water cooling system |

| Casting method | Vacuum suction cable pressurization method |

| vacuum device | Install a vacuum pump of 8L or more separately |

| Abnormal warning | Self diagnostic LED display |

| Melting speed | 2-3 minutes |

| Maximum temperature | 1500℃ |

| Temperature accuracy | ±1℃ |

| Casting pressure | Yes |

| Granulation system | Yes |

| magnetic stirring | Yes |

| Casting pressure | 1-3bar |

| Maximum steel cup size | 5"*12" |

| Smelting metal | Gold/Silver/Copper, alloys |

| Equipment size | 950*900*1300mm |

| Weight | approximately 230Kg |

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur