Hasung – 1kg Automatic Gold and Silver Bar Ingot Vacuum Casting Machine for Gold Silver

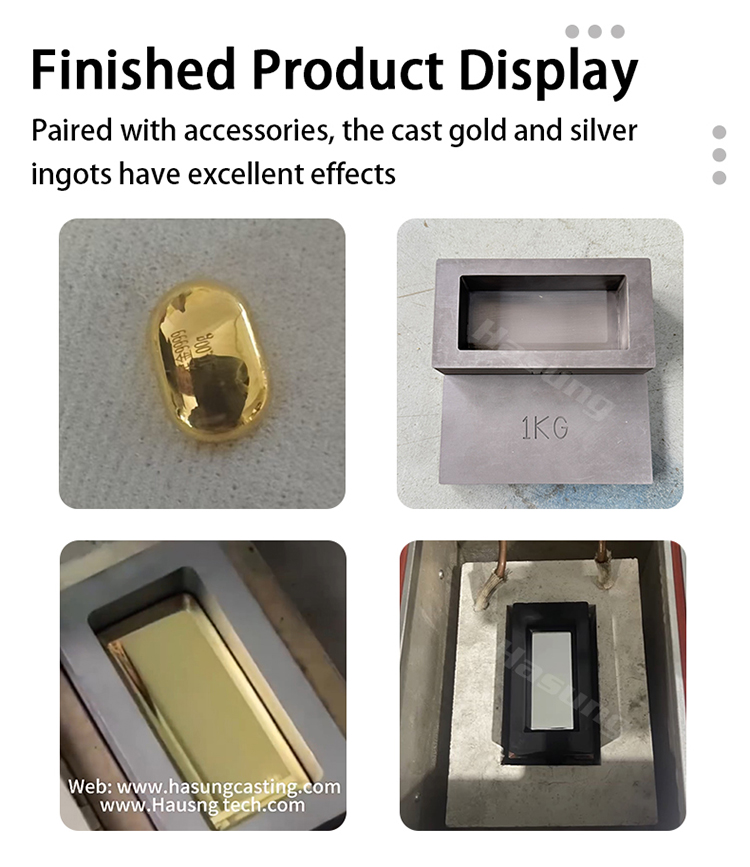

It has many significant advantages: it has a high degree of automation, greatly improving production efficiency, can work continuously for 24 hours, and has excellent production capacity performance; The quality of the produced gold and silver ingots is excellent, with a smooth and shiny surface; Supports multiple specifications, whether it is national standard 1kg, 12.5kg gold ingots, or other sizes of gold/silver ingots, it can be applied; Extremely convenient to operate, with the ability to independently and flexibly choose between automatic or manual modes; And there are multiple security protection mechanisms in place to ensure worry free use.

In terms of technology, advanced German high-frequency heating technology is adopted, with automatic frequency tracking function and multiple protection technologies, which can achieve rapid melting in a short time and effectively save energy. At the same time, the use of a closed/channel type melting chamber combined with vacuum/inert gas protection prevents the oxidation of molten raw materials and the mixing of impurities, ensuring the high purity of metal materials. In terms of control, well-known domestic and foreign brand components such as Mitsubishi PLC program control system, SMC pneumatic, and Panasonic servo motor drive are used to ensure the stability and accuracy of equipment operation.

Technical parameters:

| Model | HS-GV1 |

| Voltage | 380V, 50/60Hz 3 phase (220V single phase / 3 phase) |

| Power | 15KW |

| Casting time | 8-10 min. |

| Capacity | 1kg (Gold); 1pcs 1kg or 4pcs 200g or more. |

| Vacuum | High quality vacuum pump (built-in) |

| Cooling method | Water cooler |

| Inert gas | argon/nitrogen |

| Melting metal | gold/silver |

| Control system | Siemens touch screen + Siemens PLC intelligent control system |

| Cylinder brand | AirTec |

| Relay brand | Japan IDEC or Germany Omron |

| Operation mode | Automatic |

| Cover close and open | Manual model / Auto model |

| Equipment size | 730 * 850 * 1010mm |

| Weight | Approx. 200kg |

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur