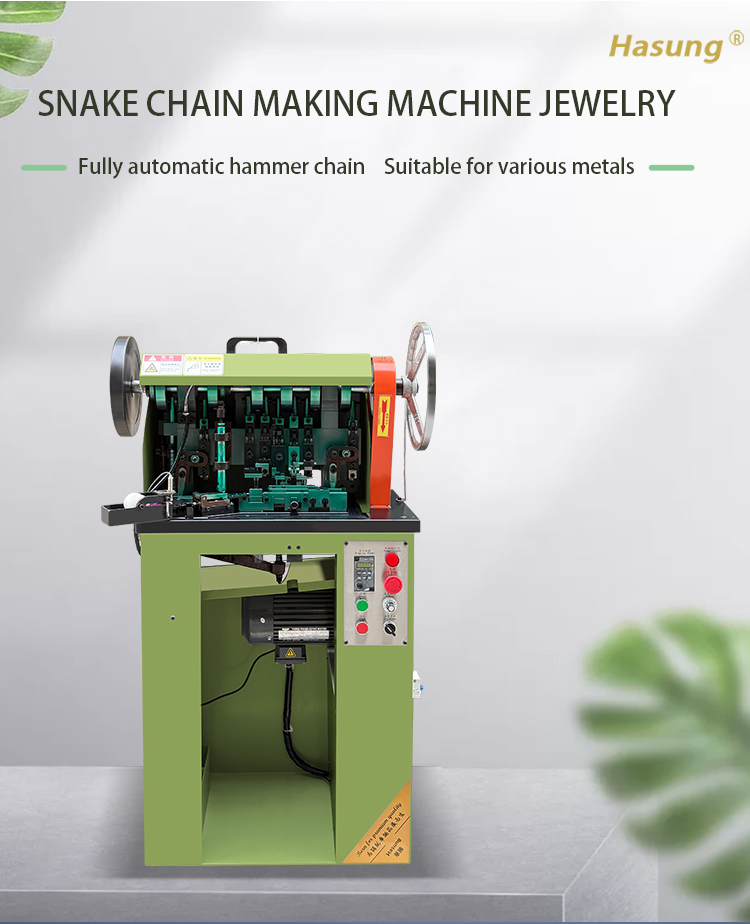

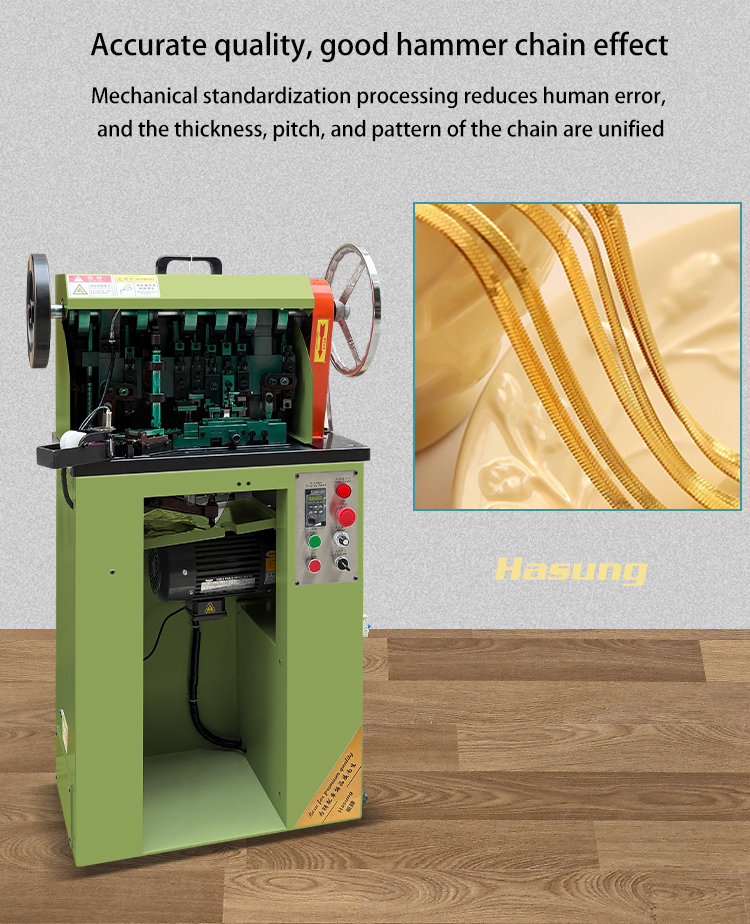

Fully Automatic Hollow Snake Bone Chain Machine

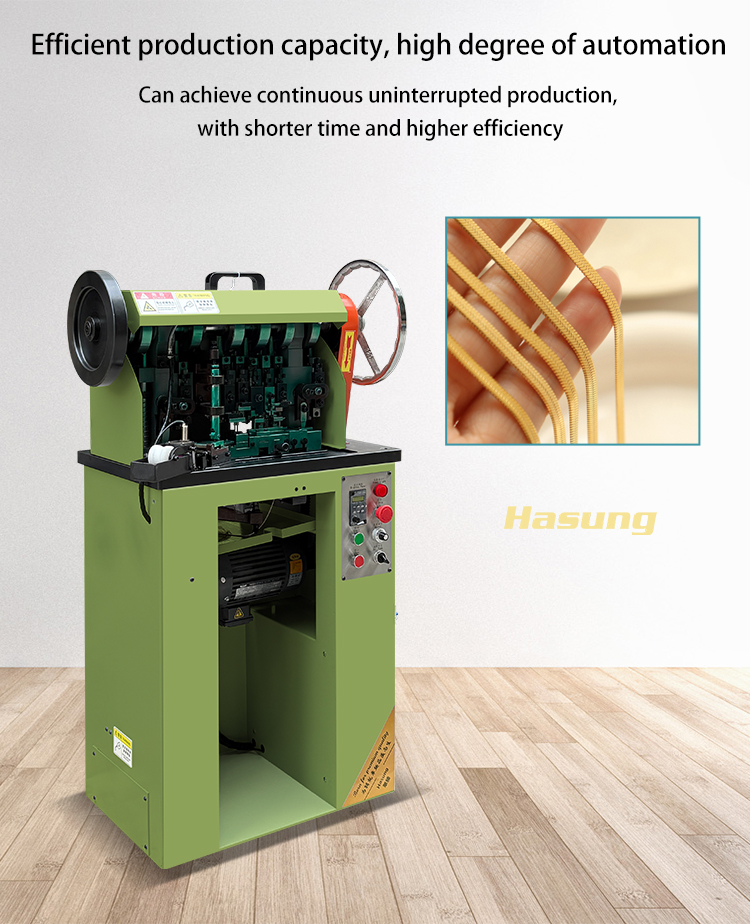

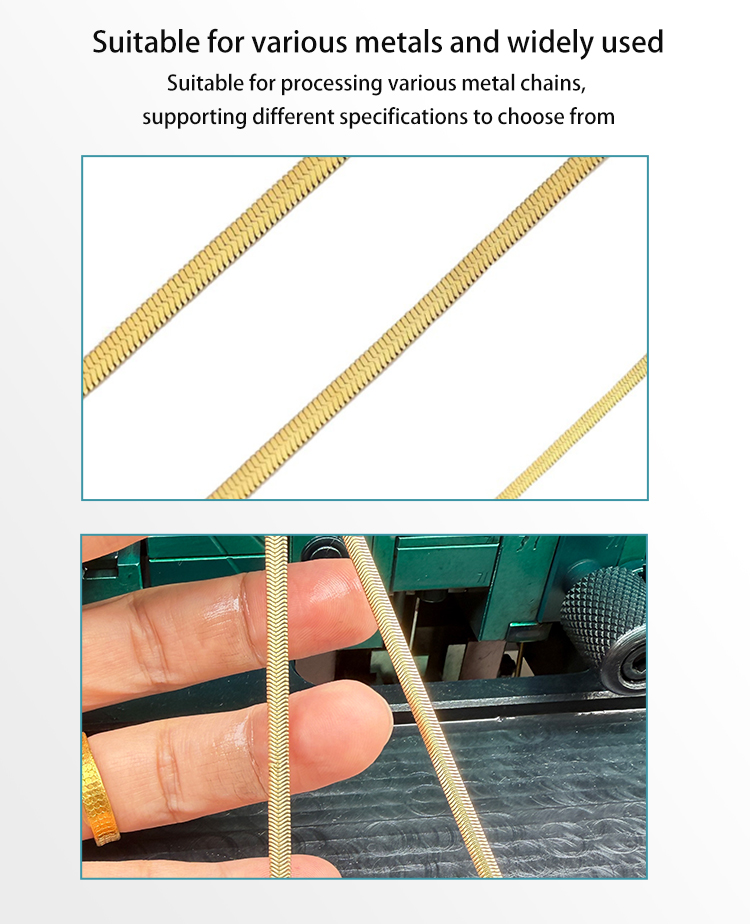

The Hasung fully automatic hollow snake bone chain machine is an automated professional equipment in the field of metal chain processing. It is equipped with precise hammer chain technology and is specially designed for mass production of hollow snake bone chains in industries such as jewelry. The equipment adopts a fully automated hammer chain structure, which can continuously produce without interruption, with efficiency far exceeding traditional manual and semi-automatic equipment. At the same time, mechanical standardization processing eliminates human errors, making the chain thickness uniform, pitch precise, and texture delicate. It also supports various precious and ordinary metal materials such as gold, K gold, silver, and copper, and is suitable for the processing needs of multi specification snake bone chains.

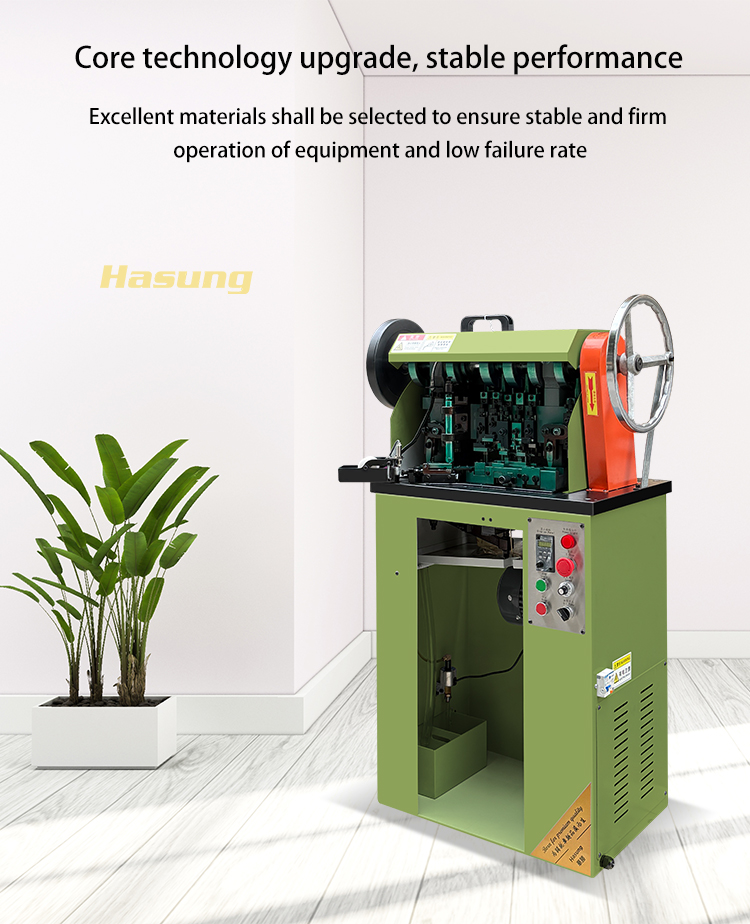

This device achieves dual upgrades in performance and safety, using high-quality materials to build the body, which runs firmly and stably with low failure rates, ensuring the stability of long-term continuous production equipment. It is also equipped with dual protection mechanisms for overcurrent and overvoltage, safeguarding the safe operation of the device from hardware to system in all aspects. At the same time, the device operation interface is simple and friendly, making it easy for beginners to quickly get started, greatly reducing the cost of human resources training for enterprises. Standardized processing can also make the finished products high-density and high-quality, providing a solid guarantee for enterprises to stably output high-quality chains.

The application scenarios of this fully automatic hollow snake bone chain machine cover various processing and manufacturing industries, and the core is suitable for the jewelry industry. It can produce high-end necklaces, bracelets, snake bone chains made of precious materials such as gold and platinum; Also suitable for the fashion accessory manufacturing industry, mass producing trendy metal chains to meet the demand for light luxury accessories; It can also be applied in the field of hardware accessories processing, creating precision metal chain accessories for luggage and clothing. At the same time, it can serve the gift and handicraft industry, customize craft gift chains, and help enterprises in various industries enhance product added value and market competitiveness.

Product Data Sheet

| Product Parameters | |

| Model | HS-2038 |

| Voltage | 220V/50, 60Hz/single-phase |

| Maximum production speed | 120 times/minute |

| Chain length speed | 5-8m/hour |

| Variable frequency speed regulation machining dimensions | 1.5-7.0mm |

| power | 500W |

| strip thickness | 0.12-0.2mm |

| Maximum diameter of steel coil | 220mm |

| Minimum Flat Serpentine Chain | 2.0*1.10mm |

| Maximum Flat Serpentine Chain | 6.4*2.3mm |

| Body size | 930*590*1300mm |

| Equipment weight | About 230KG |